Dangerous Goods Declarations are necessary for any shipper that's handling potentially hazardous items. Many of our clients deal with chemical products on a regular basis and have to deal with these declarations for every shipment.

Dangerous Goods Declarations serve a crucial purpose, but they can also consume a lot of time and energy. Even worse, using something as simple as a spreadsheet for your declarations increases the likelihood for double data entry and other manual errors. Working with an ERP that's designed for your needs will help minimize these issues.

Who Handles Dangerous Goods Declarations?

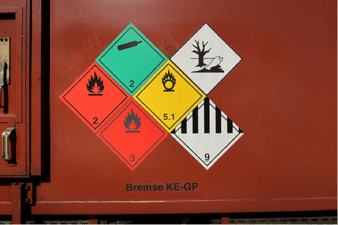

Image via Flickr by Kecko

Shippers are responsible for creating Dangerous Goods Declarations any time they're preparing potentially hazardous items for transportation. Dangerous and hazardous substances are classified into one of nine categories as specified by the United Nations Committee of Experts on the Transport of Dangerous Goods. These classes include:

- Explosives.

- Gases.

- Flammable liquids.

- Flammable solids.

- Oxidizing substances.

- Toxic and infectious substances.

- Radioactive material.

- Corrosives.

- Miscellaneous dangerous goods.

If you're shipping products in one of these categories, you must prepare a dangerous goods declaration to accompany the shipment. This critical task requires detailed information about the products that you're shipping and any dangerous qualities they may have.

Required Information

Your dangerous goods declaration must include a wealth of information about the package and its contents, so anyone handling the products will be properly informed of the potential hazards therein. The information that's required includes:

- UN or ID number.

- Proper shipping name.

- Class or division.

- Packing group.

- Quantity and type of packing (including net quantity of dangerous goods and outer packaging materials).

- Packing instructions.

- Authorization.

Proper codes and details are essential in every area. We highly recommend providing extensive training to any individuals who are involved in the shipment of dangerous goods. Everyone in the company should understand what's classified as hazardous materials as well as the specific classifications and UN or ID numbers that apply to the products that they handle.

How Automation Helps

Automating your Dangerous Goods Declarations can improve your shipping process dramatically. Automation helps cut down on employee errors and ensures that all the necessary fields are filled out. Automated software also creates a clean, legible copy of the necessary forms, without any of the confusion or hazards that may come from filling out paper forms by hand. If you're looking for an efficient way to save time, streamline your process, and minimize mistakes, automation is one of the best ways to do it.

Features of Sage ERP for Chemical Shipping Clients

Sage ERP includes features that are designed specifically for our clients who ship chemical materials. We understand the challenges inherent with this type of shipping and wanted to provide the functionality necessary to make the process as quick and easy as possible. When you're shipping hazardous materials, you have the option to complete your Dangerous Goods Declaration within the ERP. The system asks for all the essential details including packaging, net weight, gross weight, hazardous class, hazardous subclasses, flashpoint, and more.

If you're interested in finding a better way to manage your Dangerous Goods Declarations, we can help by putting the right ERP software at your fingertips.

.png)